Metal Roofing

As commercial roofing specialists, Whitco offers a wide range of metal roofing systems — from structural and architectural standing seam, to trapezoidal panel to R-panel. Whitco provides metal roof repairs, metal roof restoration (roof coatings), metal roof replacement, new installation, preventive maintenance, and energy management solutions to help improve energy efficiency.

![]()

Metal Wall Panels/Custom Metal

Unlike most commercial roofing contractors who outsource the fabrication of metal components, Whitco does this in-house, with a full metal shop including state-of-the art machinery, and a dedicated staff of experienced metal fabricators. This allows Whitco to not only craft custom metal in a fraction of the time other companies are able to, but also to pass on considerable cost savings to clients by not utilizing third-party fabricators and subcontractors. Whitco’s metal department has experience in all types of metal, including aluminum, Kynar coated metal, copper, and other hard-to-find materials. Whitco’s metal craftsmen can create virtually everything needed in a commercial roofing application, including gutters, downspouts, coping, edge metal, leaderheads, and even custom metal wall panels.

![]()

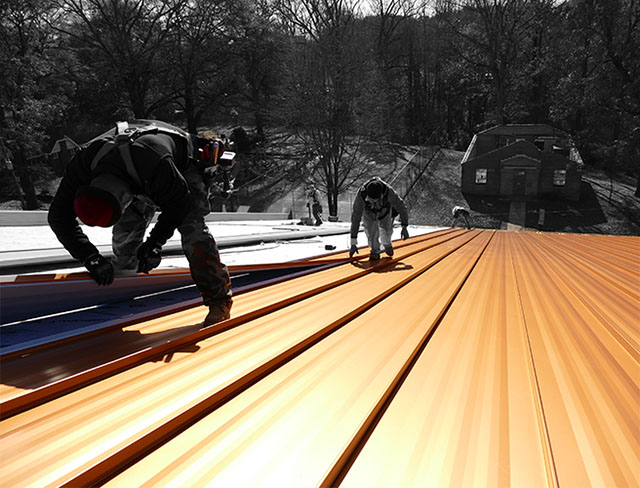

Standing Seam Metal

Metal roofs have come a long way and today’s architectural standing seam metal panel roof systems are some of the most attractive and durable options available in the commercial roofing industry. Whitco’s experienced and knowledgeable metal roofing division has experience installing architectural standing seam metal roofs on a variety of facilities, including schools, hotels, retail properties and others.

Pac-Clad/ Petersen Aluminum, Sentriclad, Fabral Inc. and Berridge are just a few of the standing seam metal roof manufacturers that Whitco is certified to install and repair. Architectural standing seam roof systems are a great option whenever an attractive, custom-colored and durable roof system is required. Available in 22., 24. and 26. gauge, as well as 032 and 040 aluminum, architectural standing seam metal can be used in a variety of applications and can provide watertight warranties up to 20 years.

Whitco’s in-house metal shop utilizes state-of-the-art computerized metal breaks imported from Germany and Whitco’s metal technicians can custom fabricate the most intricate and difficult designs any architectural standing seam metal project could require.

![]()

Stainless Steel Roofing

Stainless steel roofing can be a long-term solution to a variety of issues that plague other roof systems. However, it’s still important to incorporate preventative maintenance to ensure the life cycle of your stainless steel roof. Whitco is experienced in installing and maintaining stainless steel roof systems. Whitco’s services include repairs, restoration, replacement as well as management and maintenance.

If you are having issues with rust, or your metal roof is corroding from exposure to chemicals, a stainless steel roof may be a good option for you. If another contractor has told you it can’t be done, we encourage you to contact Whitco Roofing. A Whitco client needed to replace a metal roof after harsh industrial conditions left the galvanized steel damaged. This client had many contractors tell them that the project was impossible. Whitco’s expert team provided a solution — designing and manufacturing custom structural stainless steel panels that were fitted specifically for the client’s roof. Whitco’s knowledge and experience of not only roofing, but also architectural design, allowed them to provide their client with the solution they needed.

![]()

Metal Retrofit Systems

If your metal roof needs upgrades or repairs, adding a single-ply membrane is another cost-effective solution that also provides long-term protection. Metal retrofit systems have become increasingly popular in recent years, as building owners and facility managers become frustrated with the constant maintenance required from certain types of metal buildings due to ongoing expansion and contraction. Retrofitting a metal roof also adds insulation, which provides an increased R-value for the building, and saves on heating and cooling expenses. Whitco’s project portfolio includes many metal retrofit systems, an increasingly popular method being utilized by building owners. Metal-over-metal retrofit roofs are another option, and typically involve the installation of lighter metal panels over the existing metal roof.

![]()

Certification

Whitco Roofing, Inc. is an NRCA ES-1 authorized fabricator.

The ES-1 standard protects the public from flying metal debris due to strong wind currents. It greatly reduces the risk of edge failure which can ultimately result in failure of the overall roofing system. Therefore, this standard also protects the owners’ investment.

The purpose of the ES-1 standard is to improve longevity and safety for low-slope commercial roofs by incorporating quality edge metal systems which include fascia and coping.

ES-1 Certification is universally required by the International Code Council and has been adopted by every state in the US but is time-consuming and difficult to obtain. Working with Whitco Roofing, Inc. as an ES-1 certified roofing company, we can assure you that we are so confident in our metal and the work that we do, we voluntarily paid to have it independently tested.

![]()

Pre-Engineered Metal Buildings

Pre-engineered standing seam metal buildings provide a low-maintenance, long-term roofing solution and boast exceptional wind-uplift ratings and longevity. Manufacturers like Butler® and A&S offer innovative metal roof systems that combine waterproofing and building insulation in one package. Most pre-engineered roof systems are comprised of concealed fasteners and clips. The metal panels are crimped at the seams to create a monolithic metal surface over the entire surface of the roof.

Whitco’s metal roofing division can design and build pre-engineered buildings from the ground up, including all walls and support members.

![]()

Coatings

Adding a roof coating to a metal roof can provide waterproofing, prevent rust, and extend the life of a metal roof system. Coatings can also improve energy efficiency, helping reduce annual heating and cooling costs.

![]()

Preventative Maintenance

Metal roofs are known for their strength and durability, but still require periodic repairs and preventative maintenance. To protect your roof from water damage and rust, be aware of the following risk factors:

Risks For Rust:

- Exposure to weather (rainfall, ponding water, moisture, corrosive substances in the air)

- Harsh industrial conditions

- Age of the building

- Foot traffic which can cause broken corrugations

- Deterioration of factory coatings

- Overtightening of fasteners during installation

- Debris left on a roof

- Building movement

Risks For Leaks:

- Rusted metal panels

- Loose seams and cracked penetrations (expansion or contraction due to weather)

- A system overloaded with equipment

- Clogged or improperly sized gutter systems

- Poor construction and/or poor design

- Loose or missing fasteners

- Lack of maintenance